How To Install Braided Fuel Lines

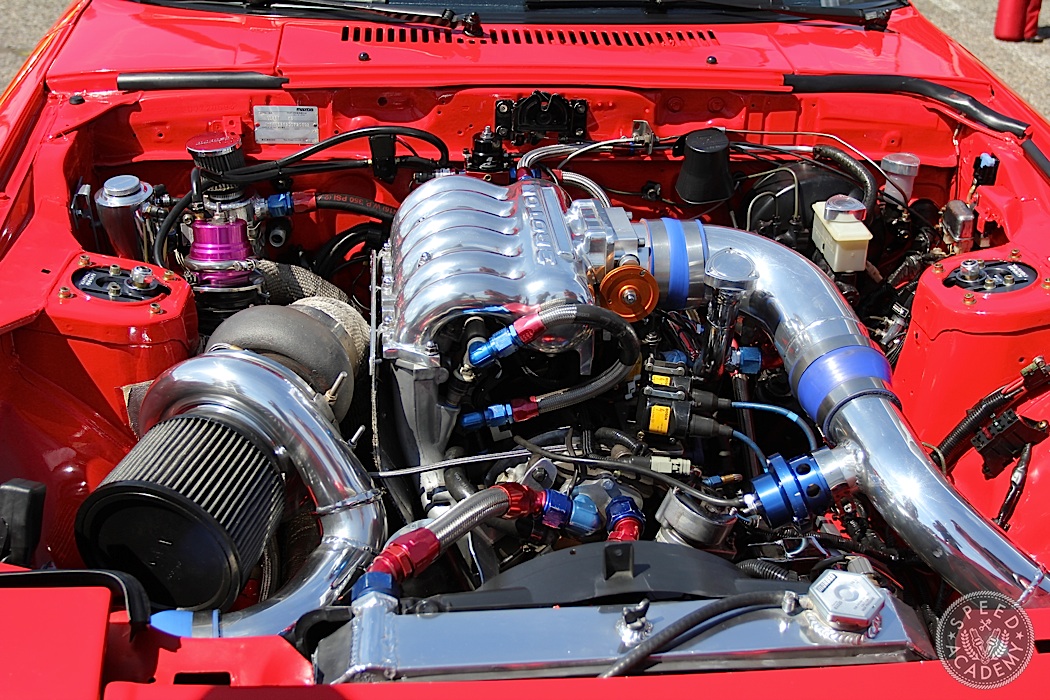

Fluid transfer in high performance engines is a vital role to ensure proper fueling, lubrication and cooling. With these Motorsports applications seeing higher operating pressures and period rates, conventional connection methods may non suffice.

To ensure reliable and secure connections AN-fittings have been adapted from their armed services purpose to Motorsports applications. AN (Army & Navy) fittings pass a articulation standard betwixt these 2 military machine branches. If it tin can perform under warfare conditions, so it should be good plenty for our applications.

People may be turned off past AN fittings thinking that it is complicated to assemble, I was ane of them. Still, afterward assembling my first AN hose, it is relatively simple. Hither are unproblematic steps to gather your ain AN hose for your application.

For our application we volition use AN-fitting hose ends. They consist of 2 parts; a male and female fitting. Obviously you will too need hose. For our awarding we are using Vibrant Performance Stainless Steel braided -10AN hose.

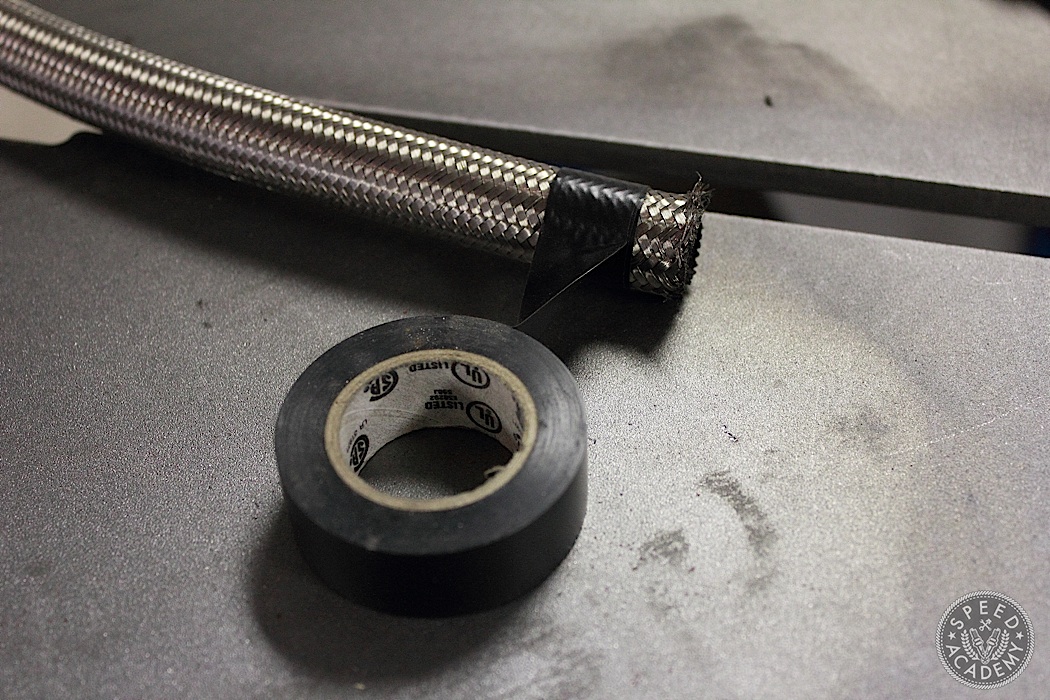

One time yous have marked the required length(due south) to exist cut, I find that wrapping the end with electric record earlier cutting it decreases the fraying of SS braided hose.

There are various ways of cutting SS braided hose, some people use cutters, hack saws or cut off wheels. I institute success with an angle grinder with a metal cut off bicycle as it seems to take less fraying. Practice not forget your middle and ear protection if you are using any sort of cutting power tool.

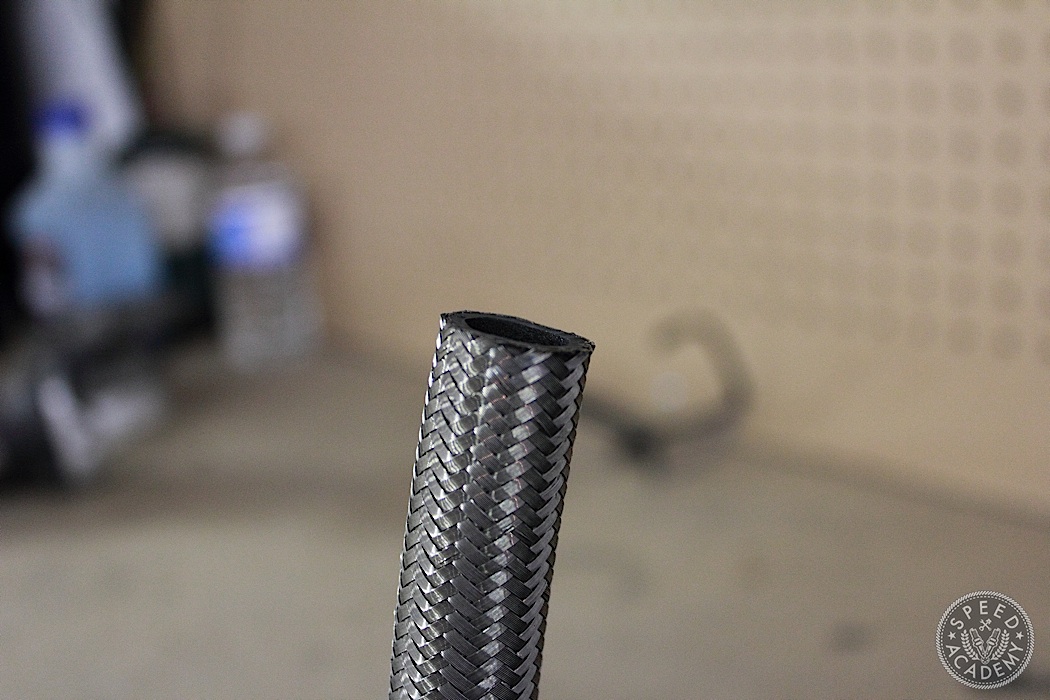

If you lot are lucky then y'all will end up with a hose end similar this. Make sure the hose is level effectually its diameter to ensure an even mating surface with the inner lip of the female AN fitting.

If God hates you then you'll end up with a frayed stop like this. This tin can also result when reusing a hose that had previously been fitted with an AN fitting. Anyone that has assembled SS braided hose will tell you that they would rather stand on Lego pieces and mouse traps than bargain with frayed ends. The private strands will stab yous repeatedly until you and the hose are covered in claret. In extreme cases, information technology is best to cut the end off and start over.

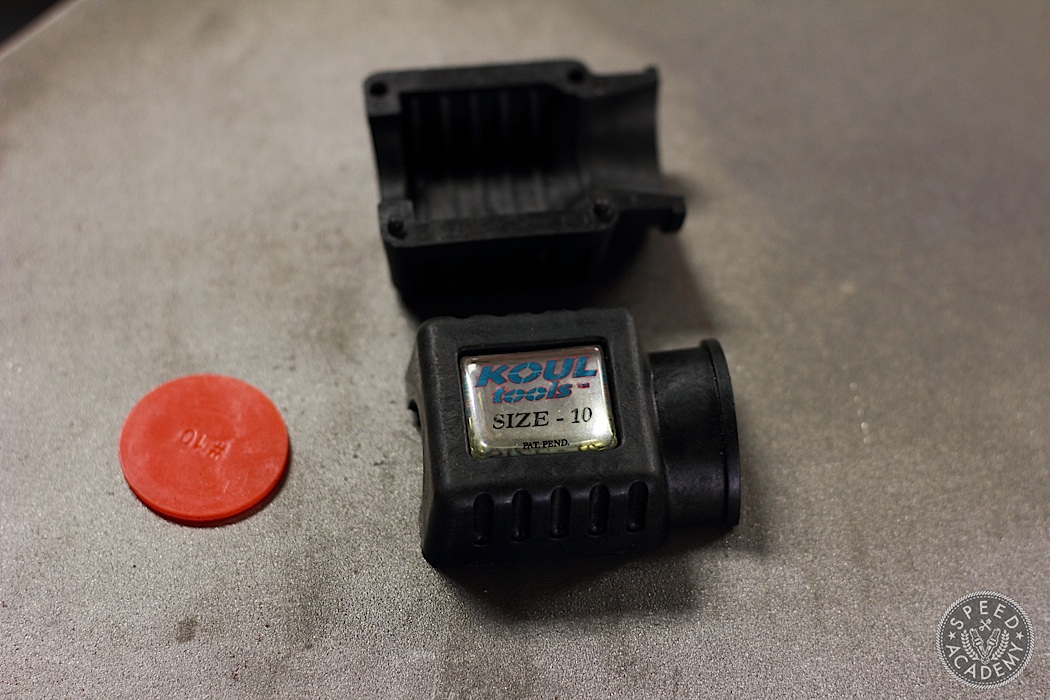

If you are only assembling a hose or two and so it may not carp you that much. In my case I was assembling multiple stainless steel braided hoses for the fuel, oil and cooling system. Having endured some stray SS strands despite my best attempts with a clean cutting I was ready to quit. Luckily I stumbled onto the "Koul Tool". If y'all are using nylon braided hose then you will be fine without this tool.

The tool itself is fabricated from durable plastic composite that is virtually indestructible. The kits range from -4AN to -16AN. It has spacers to accommodate nearly pop AN fitting brands.

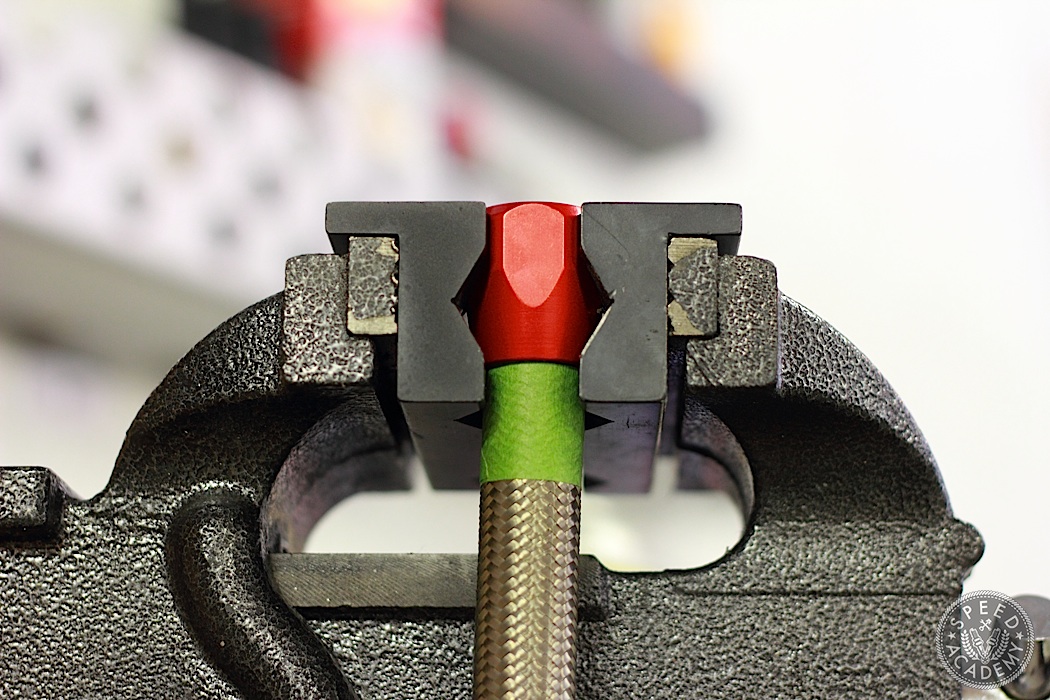

You simply put the AN hose end into the tool and utilise the spacer if needed and shut the tool. You can run into the bottom opening that has a tapered opening to funnel the hose into the AN fitting.

Set the tool in a vice and tighten until information technology is secure. The tough plastic tin tolerate the pressure from the vice but use mutual sense and don't over clamp it as it can and volition crack.

With the tool secure in the vice, have your AN hose and push it into the fitting by turning it clockwise while applying forward pressure towards the fitting.

The hose should finish at the within lip of the fitting before the treaded department like and so.

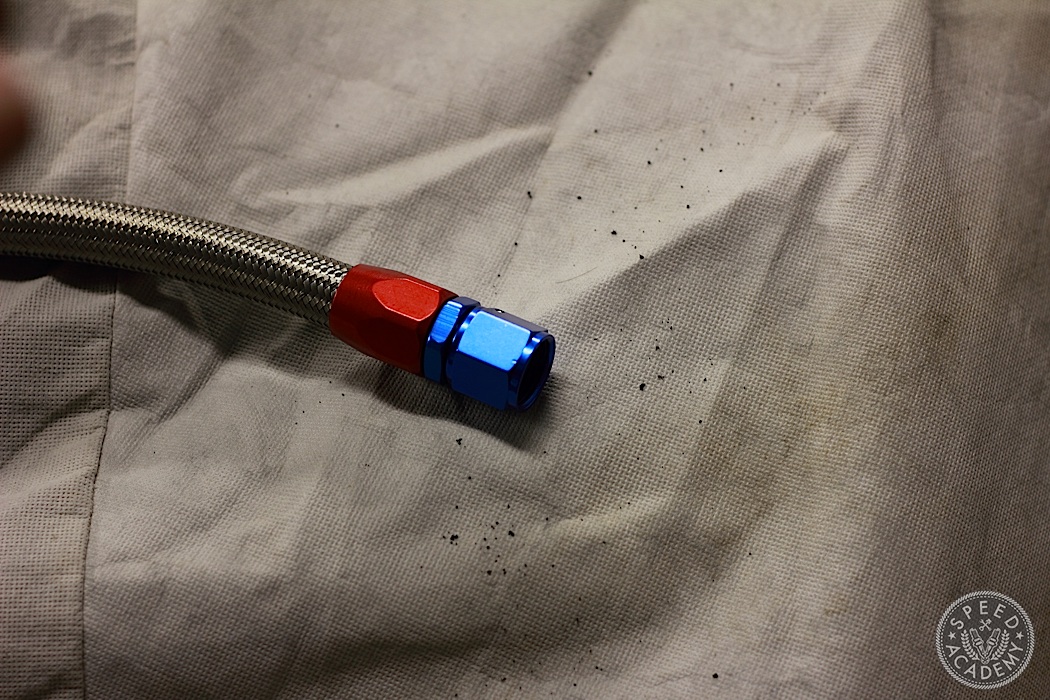

This is what your newly inserted SS hose looks similar when the Koul tool is removed, clean and complimentary of blood. Of course you don't have to get this tool but if yous are going to be assembling diverse fluid transfer organisation hoses like I was, then it is an excellent addition to your tool armory.

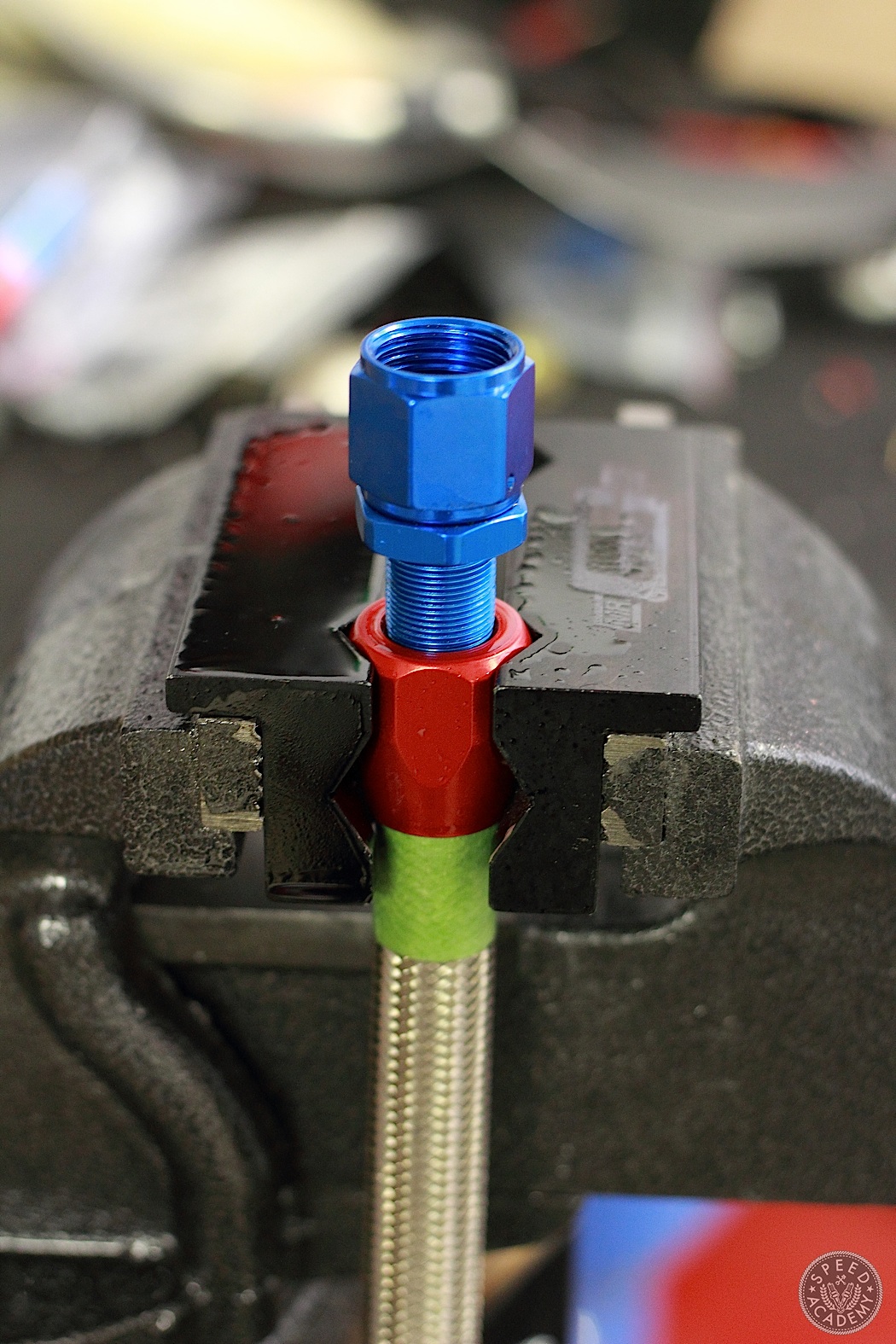

Speaking of having the right tools, nosotros picked up these aluminum vice inserts to agree the AN fitting and hose in place while installing the AN hose end. The aluminum insert has angled provisions to hold the AN fittings in identify without galling or damaging them. They have magnetized inserts to hold them in the vise.

Hither's a pro tip, wrap tape on the hose and make sure the straight edge of the tape is right against the AN fitting. The purpose of this is to see if the hose gets pushed down and away from the within lip of the plumbing equipment when installing the male person hose terminate.

This is the male AN hose end in question. Equally the plumbing fixtures is screwed onto the female person AN section, at that place is a possibility that the inner safety hose will get pushed away inner lip of the female AN fitting causing leaks. The tape gives you a visual indicator if this has happened. Spraying WD40 or silicone spray before screwing in the fitting helps the male end slip into the hose easier.

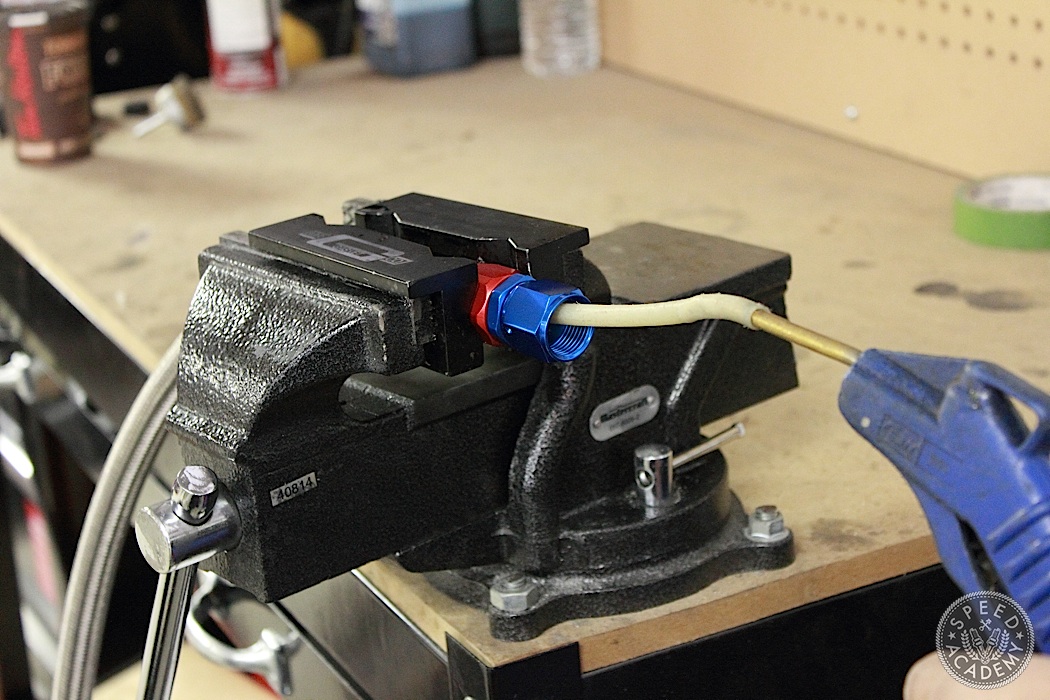

Using an AN wrench or equivalent wrench, tighten the fitting into the hose end. Applying an upward pushing motion on the hose simultaneously every bit you tighten the fitting into the hose also helps to combat the trend of the hose to be pushed downward.

Voila! Here is the finished product. As you lot can see the record remains tight against the lower fitting. If a large space develops betwixt the tape and plumbing equipment then you will have to remove the male fitting and redo the process again until you achieve this result.

But wait in that location's more! Make sure that your assembled hose is clean and gratuitous of debris. I found the combination of pressurized air and brake cleaner produced keen results.

Yous definitely would not want any of this to make its way into your fuel, cooling or lubrication systems and cause preventable damage. I recommend taping upwards the ends of your assembled hoses subsequently you have cleaned them until yous are ready to assemble your cooling, fuel or oiling systems. After that, welcome to the world of reliable leak free fluid transfer!

Source: http://speed.academy/how-to-assemble-an-fitting-hose/

Posted by: emersonscrims.blogspot.com

0 Response to "How To Install Braided Fuel Lines"

Post a Comment